Technical considerations in building reinforced soil walls

Reinforced soil walls have proved highly popular in recent years and are produced wherever possible, taking the place of concrete-faced soil retaining wall systems.

Employed in a range of different environments, they bring significant advantages, both financial and environmental. Indeed, unlike concrete-faced soil retaining wall systems, they:

- are sustainable because they give a vegetated finish;

- are a great space-saving solution, with slopes as steep as 80° (compared to the 30-40° of natural soil embankments);

- result in less pollution given the smaller number of trucks required to carry construction materials;

- make use of the excavated earth for backfilling, provided it is compatible with stability standards, meaning no more material needs to be brought in;

- blend seamlessly with their surroundings once the slopes are grassed over, without becoming a blot on the landscape of our villages.

Whatever the case, before planning the work, there are a number of aspects and data to be taken into consideration.

Preliminary data needed

To start with, all essential technical information must be procured in order to be able to assess the feasibility of the project, such as:

- geological testing of the area on which the wall is planned to be built

- topographical surveys

- meaningful cross-sectional drawings showing the current condition

- geometry of the planned wall (face angle, height, division into tiers, slope on top)

- external loads applied to the structure (top loads in the event it needs to accommodate a car park or a road)

- what earthquake risk zone the area is in

- geotechnical properties (angle of shearing resistance, cohesion and density) of the earth behind the future wall, of the foundation soil, and of the backfill

- whether there are perched aquifers or seepage of a different nature.

At this point, the next step is to check design calculations using specific software.

Checking design calculations

Checking is performed to assess both internal and external stability. The following tests are carried out in the former case:

- reinforcement strength test, which assesses possible failure mechanisms and determines the spacing, length and tensile strength of the geosynthetics due to be laid

- pull-out test to check that the reinforcement applied does not break or slide out

- direct sliding test, to ensure there is no translational movement across the installation planes

- wrap-around test, to ensure that the length wrapped around the top of each individual layer is stable.

The checks to be carried out during the project’s execution to assess external stability consist in sliding, overturning, bearing capacity and global failure analysis.

Do you want to chat with one of our experts to find the solution that best suits your requirements?

We have 30 years of experience in the industry and can give you access to materials and solutions offering specific performance. Contact us!

Do you want to learn more about the full TeMa Geo Solutions product range for reinforced earth structures? Click here.

- Published in Drainage geocomposites and membranes, environmental, GEO, Geogrids, Reinforced earth structures, Reinforced earth structures - Drainage, Reinforced earth structures - Erosion control

Tips for the correct laying of TMD 1011

For vertical applications, such as foundation walls, and for horizontal applications, such as flat roofs, mechanical protection of waterproofing is required and, often, also drainage: TMD 1011 is a studded membrane, produced by TeMa Building Solutions, that performs both functions: drainage for vertical applications and waterproofing protection for horizontal applications.

A few tips for laying TMD 1011 on horizontal surfaces

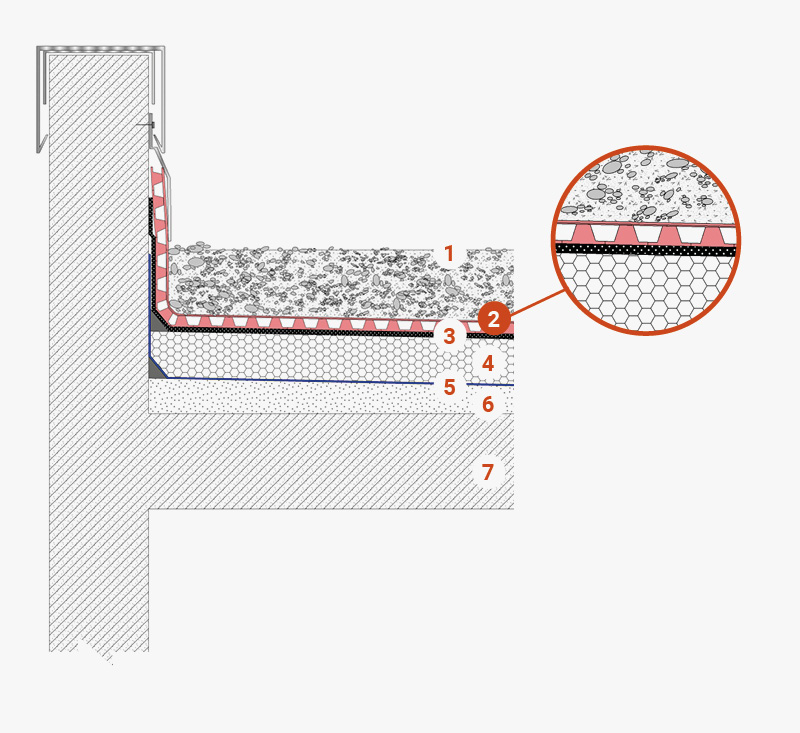

Flat roof with gravel finish (weighted)

1 Gravel finish

2 TMD 1011 membrane serving as a drainage layer and for waterproofing protection

3 Waterproofing membrane

4 Thermal and acoustic insulation

5 Vapour barrier

6 Sloping underlayment

7 Load-bearing structure

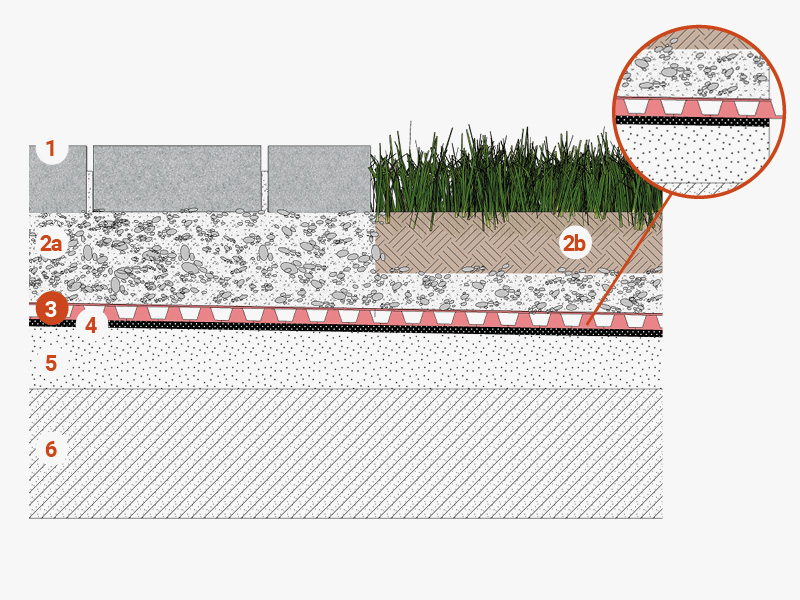

Walkways and green areas

Walkways and green areas

1 Interlocking block paving

2a Crushed stone bedding course

2b Growing medium

3 TMD 1011 membrane serving as a drainage layer and for waterproofing protection

4 Waterproofing membrane

5 Vapour barrier

6 Sloping underlayment

7 Load-bearing structure

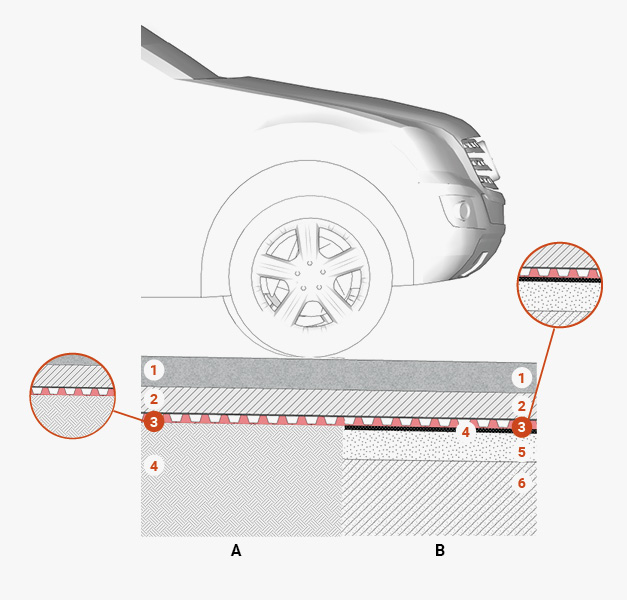

Surfaces suitable for vehicle traffic A

1 Paving designed to take vehicle loads

2 Sand bedding layer

3 TMD 1011 membrane serving as a:

– drainage layer

– substrate in place of traditional concrete levelling compounds

– separating and leachate containment layer (oils or hydrocarbons)

4 Substructure / ground

Surfaces suitable for vehicle traffic B

1 Paving designed to take vehicle loads

2 Sand bedding layer

3 TMD 1011 membrane serving as a drainage layer and for waterproofing protection

4 Waterproofing membrane

5 Sloping underlayment

6 Load-bearing structure

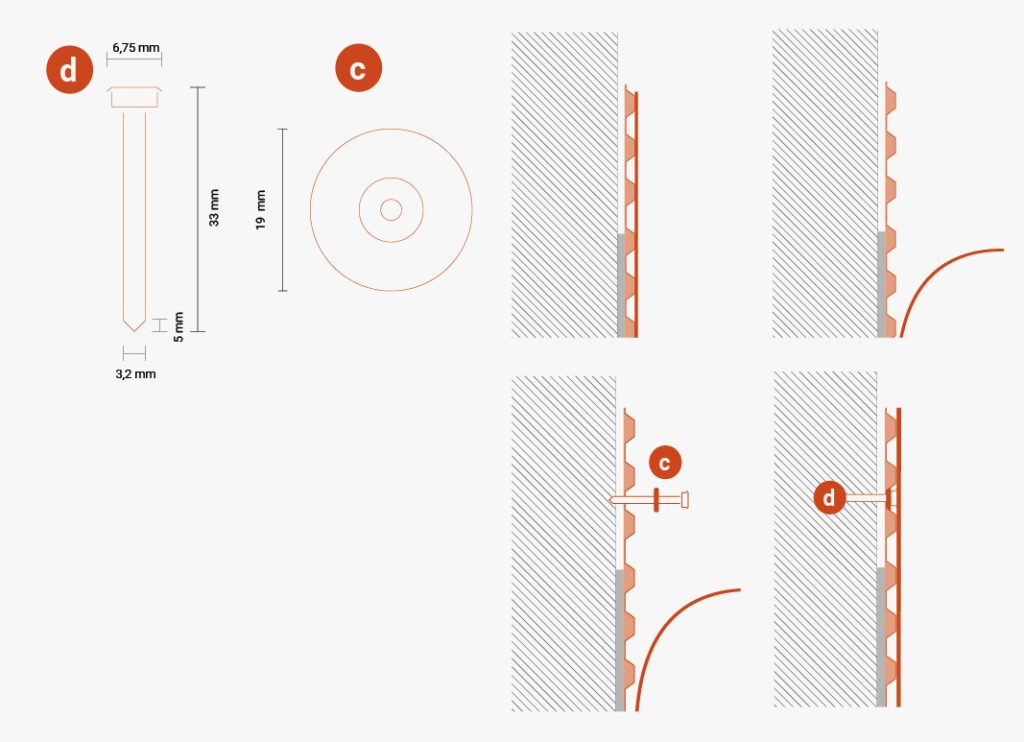

A few tips for laying TMD 1011 on vertical surfaces

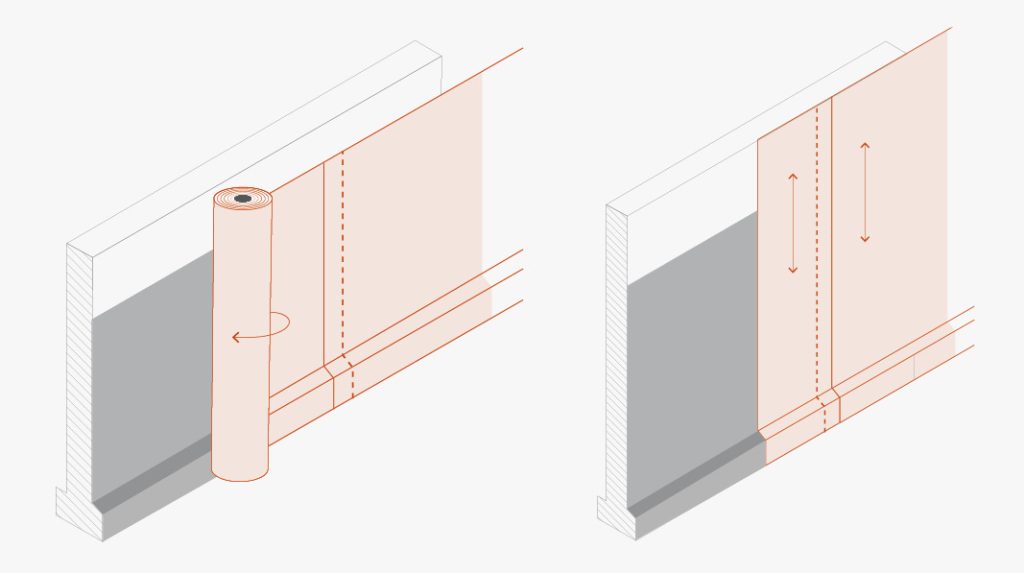

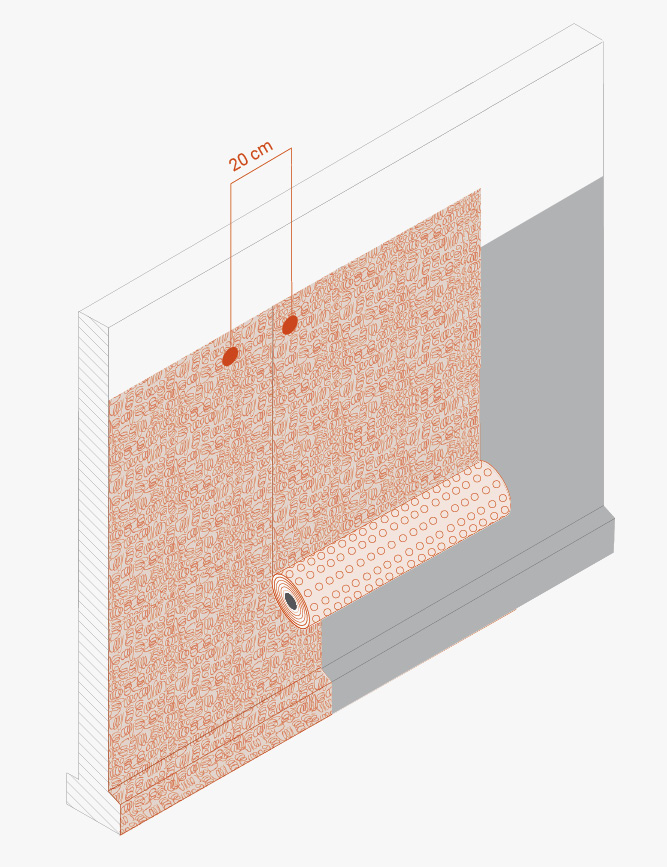

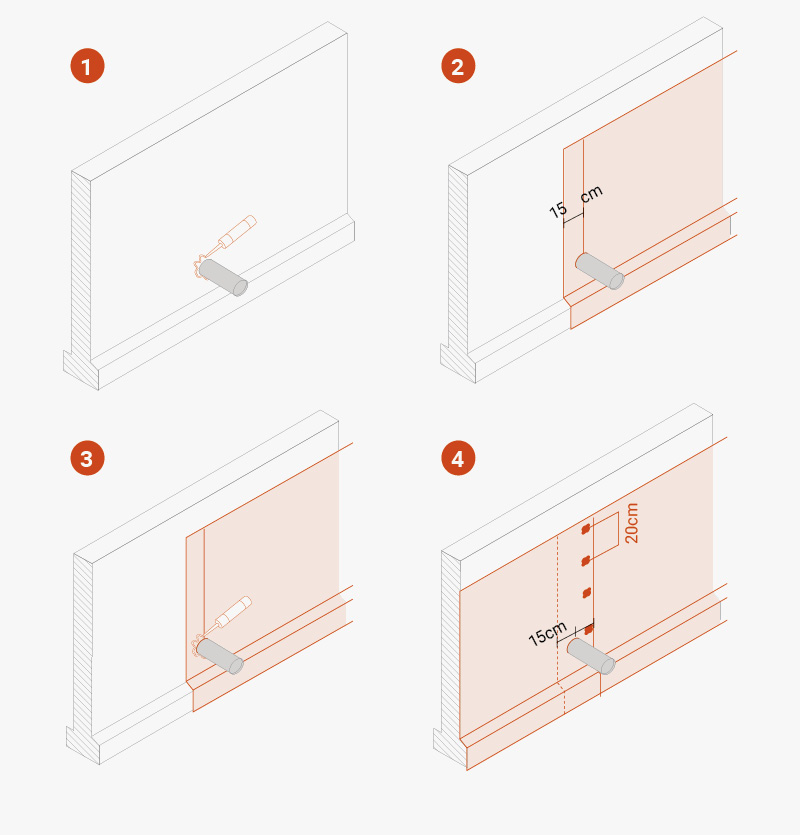

Unroll the membrane and install it vertically or horizontally: in the latter case, the width of the roll corresponds to the height of the wall to be protected. Two consecutive membranes should overlap by about 20 cm, and the studs should interlock.

For horizontal joints, if the TMD 1011 membrane is not wide enough to completely cover the height of the installation, the first layer should be installed from the base upwards and then, keeping an overlap of at least 15 cm, the second layer should be installed by overlapping the first layer outwards (i.e. towards the side away from the wall). Install washers every 20 cm in the overlapping area.

Inlets for utility connections, such as water, gas, sewers or similar pipelines

- Place mastic sealant around the pipeline or inlet.

- Cut the TMD 1011 membrane vertically so that it extends 15 cm beyond the pipeline or inlet, trimming the membrane so that it adheres as tightly as possible.

- Put mastic sealant on the membrane so that there is a layer of mastic both above and below the membrane around the pipeline or inlet.

- Start the next installation of the membrane 15 cm before the pipeline or inlet so that the overlap around the pipeline or inlet is 30 cm. Trim again around the pipeline or inlet for watertightness.

- Install fasteners every 20 cm along the edge of the overlapping membrane.

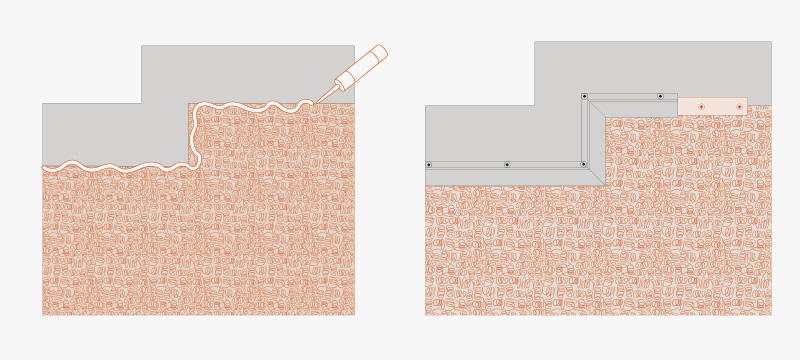

Change of level or areas where the smooth part has been trimmed

Use T-Profile + T-Nails to seal the edge, using a sealant for the area to ensure that the edge is properly sealed.

TMD 1011 should also be protected with T-Profile to prevent soil from penetrating into the gap between the wall and membrane. Then, fasten it using washers and nails with T-Nails spaced at intervals of 20-30 cm, either along the upper edge of the studded membrane or along the profile.

Cycle and pedestrian paths: solutions to make them safer and more attractive.

Longer days, milder afternoons, a great desire to spend time outdoors and perhaps get some physical exercise, but also go to work and school or visit a friend… These are all good reasons for using, when available, cycle and pedestrian paths, possibly far from urban traffic.

The advantages of sustainable mobility

We are increasingly talking about environmental sustainability and the physical and psychological benefits of physical exercise:

- Less air and noise pollution caused by traffic.

- Reduced transport costs.

- Greater freedom of movement.

- Enhanced green areas in cities.

- Better quality of life by doing a bit of sport on a daily basis.

TeMa Geo Solutions for safety and urban benefits

‘Unequipped’ roads can be hazardous for those who choose to get around by bicycle: for this and environmental reasons, cycle and pedestrian paths are the ideal solution, as they are increasingly becoming part of local government mobility plans.

TeMa Geo Solutions offers all its experience by combining reinforced earth structures and their feature of being green, with cycle and pedestrian paths.

An embankment can be made or a road widened with its sides sloping at 65°/70° using the T-System (consisting of formworks, X-Grid PET geogrids and K-Mat FG Green erosion control mats as facing), thereby making the path safe and allowing a slope to turn green again. Making a slope green again provides a natural erosion control function: to encourage it, TeMa Geo Solutions recommends installing natural or synthetic mats. To make the structure stable, the T-System for reinforced soils adopted by TeMa involves using X-Grid PET geogrids.

Drainage for diaphragms and berlin walls: a practical and safe solution

Some of the most widely used works in the civil engineering field are diaphragms and berlin walls, which counteract strong thrusts of the soil and prevent landslides and structural subsidence.

Diaphragms are supporting walls consisting of pointed vertical elements (piles) or continuous elements (walls) made of steel or reinforced concrete. They are driven into the ground to a considerable depth, whereas Berlin walls are flexible retaining structures constructed with vertical micro-piles.

Both solutions are used where it’s impossible to construct excavation walls of an adequate gradient due to the presence of other nearby structures and to the morphology of the area , which imposes limited work spaces (that would make manoeuvring large machinery impossible).

Berlin walls made of micro-piles are one of the most popular applications on construction sites for implementing waterproof retaining works. The technique allows work to be carried out on almost all types of terrain, especially when it’s necessary to use on-site systems that are smaller than in the past.

Since works are in contact with the ground, the drainage aspect should not be underestimated. If rainwater and groundwater exert pressure on the vertical wall, they may damage the waterproofing. TeMa Building Solutions therefore has the right product for this application: T-Mix Drain WP, the geocomposite that not only drains but also provides the functions of filtration, separation and stay-in-place formwork.

TeMa has acquired considerable experience with geocomposites. For many years, the company has been providing this system to replace the conventional gravel drainage system. The results are long-lasting and it’s the ideal solution: compared to conventional gravel, it’s less bulky, easily transported and quick to install. This reduces the costs of transport and implementation and on-site construction time while, last but not least, resulting in considerable savings in terms of CO2.

Fields of application

As mentioned above, diaphragms and berlin walls are widely used where space is limited. More specifically, they can be used in the construction industry, for example for underground garages in homes or commercial premises, for basements. They can also be used in river works, such as quays and piers for boats, or in earth dams and wells.

Having the experience of TeMa technicians and tested effective products such as T-Mix Drain WP at your disposal is therefore a guarantee for your construction site.

Literally putting them to the test.

Ensuring that products fulfil the required functions and standards has been our mission since the outset of our company. All materials exposed to sunlight, moisture and temperature changes are exposed to the damaging effects of nature. There’s also erosion due to rain, which can play a major role in the deterioration of many building materials.

It’s therefore important to work with institutes that have weathering test equipment and expertise in testing services for the building materials industry, for residential and commercial construction.

Why it’s important to test solutions

Each company like ours aims to meet the expectations of those who choose it and, of course, to comply with all applicable regulations. Testing the solutions we provide allows us to guarantee performance also under critical conditions, offering our customers cutting-edge products, and to support designers in planning and installers during the installation stage. As for innovation, our customers’ expectations are always very high: indeed, dozens of new products are being tested and waiting to be introduced into the market.

The tag-line of the specialised divisions of TeMa is ‘Solution’ and, to be true to this requirement, a product must meet a series of specifications of on-site competitiveness, service effectiveness and a long life.

The tests involve special equipment for testing durability, compressive and tensile strength, drainage capacity and mechanical protection, ventilation and vapour diffusion performance, thermal and corrosion resistance… as well as many other functions viewable here.

This is all achieved as a result of the close connections between our Technical Department, where market demands are examined and possible solutions studied, and Labs, where tests are carried out to check performance and guarantee performance parameters. By working with accredited independent external labs for testing procedures, we can improve throughout all stages of the production process.

Our certifications

CE marking is featured on all product lines in our catalogue, in compliance with the CPD (Construction Product Directive) 89/106/CEE. The pursuit of excellence has led us to implement a certified quality system, UNI EN 3001:2000, which ensures performance levels throughout production. We also hold various international patents.

Activities at TeMa labs

- Raw material testing: we check the quality of raw materials.

- Support for R&D: our solutions are the result of continuous research into market requirements and constant improvements.

- Supervision and monitoring of production processes: we check that production processes comply with standards and the studies undertaken.

- Quality and performance testing of end products and prototypes: tests to check performance, initially of prototypes followed by end products.

- Spot tests on production batches and conformity checks: on end products and by testing application solutions.

- Quality control: we check that products meet the standards of individual countries and the required performance.

- Drafting and updating of product data sheets: each product has its own data sheet, promptly updated, with technical data indicating its performance.

- Certifications: those required for each country in which we operate and the environmental certifications to be guaranteed for our customers.

Find out more on the dedicated page of our website.

- Published in CORPORATION, Research and development, TeMa Technologies and Materials

Reinforced earth structures and drainage

For the extension works at the Serravalle Retail Park shopping centre in the Piedmont region, we helped the company choose the solutions to implement and assisted with verifications.

The area covering about 2,000 sqm required some intervention work regarding reinforced earth structures and drainage. In particular, we undertook the preliminary work for extension works dating back to 2016.

To the south-west of the building, the soil was secured and then surfaces were replanted with greenery.

Let’s see how this was done in more detail.

Type of intervention

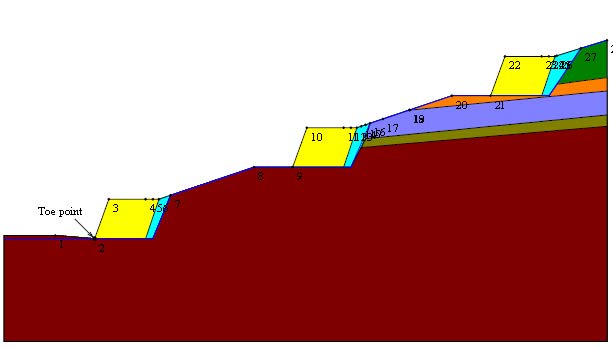

In order to make the slope in front of the complex secure, the intervention work involved constructing reinforced earth structures in several banks, more specifically 3 modules of 6 m in height each.

In addition, to manage the water coming from the hydro-geographic basin situated upstream of the area, specific surface drainage works were carried out.

The solution from TeMa Geo Solutions

For the reinforced earth structure, 3 modules were constructed with anchorage lengths of 7 m and a strength of 110 kN/m provided by X-Grid PET PC 110 geogrids.

As for drainage, instead, a Membrana Nera Geo was used, the 8 mm HDPE studded membrane bonded to a filter nonwoven geotextile with a PE slotted tube at the base.

The drainage system was also installed at the horizontal contact points of each berm to prevent future water seepage into the reinforced earth structure.

Waterproofing when concrete casting

Concrete casting involves creating a new concrete element as a continuation of an already existing one. Most often it’s impossible to create a monolithic block with a single casting: consider, for example, very large structures or the connection between vertical and horizontal walls. With concrete casting you can obtain monolithic structures with their own characteristics, built in stages at subsequent times. So, you proceed with small blocks and join each casting to the previous one, creating a monolith piece by piece.

Structural connection is achieved by using reinforcing irons, taking special care with drilling the existing block and the length of anchorage. While ensuring attachment to the sequence of blocks, reinforcing irons are potential lines for water seepage. We well know that accumulation of moisture in walls may have very severe consequences: structural fragility and very unhealthy stains and moulds.

An effective solution is to insert bentonite kerbs which waterproof any voids that may have formed at the base of walls or in contact with reinforcing irons. The intrinsic property of sodium bentonite is exploited, which is the ability to swell on contact with water, filling the available space and forming an impermeable compound.

Furthermore, this material provides high resistance to hydraulic load, is easily applied and adheres perfectly to the support.

The range of building products from TeMa Building Solutions also includes T-Bentostop, the waterstop made of hydro-expanding bentonite for waterproofing and sealing concrete casting.

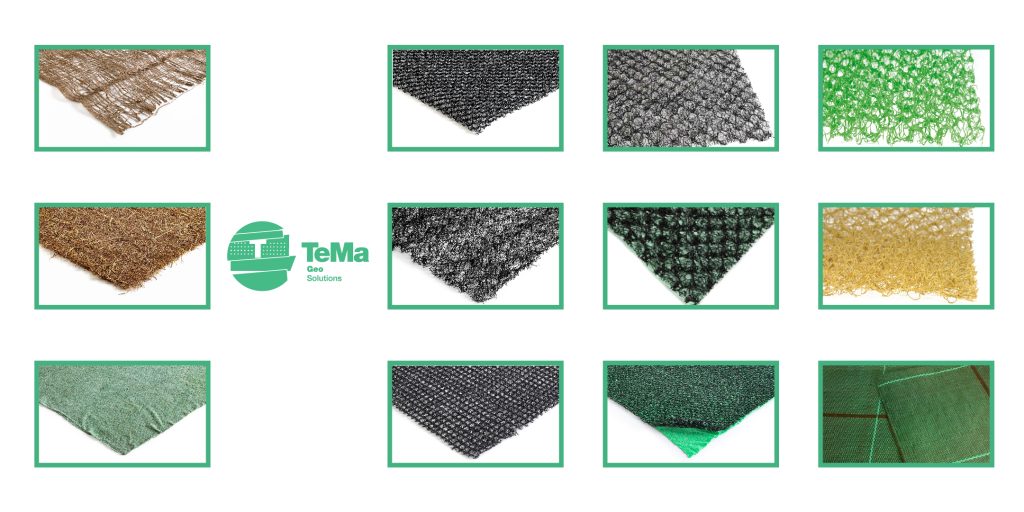

Controlling surface erosion with biomats and geomats

Soil erosion is an almost inevitable natural phenomenon that has become a greater concern in recent years due to the worsening climate situation – in Italy, for example, 132 extreme weather events were recorded between January and July 2022, a higher number than the annual average over the last decade – combined with long periods of drought.

Strong winds, heavy rain, hail and runoff tend to remove the surface layer of exposed soils, which often include organic matter and seeds. Climate change facilitates erosion, making it not only inevitable but also hazardous if left uncontrolled.

It’s essential to counter or mitigate the phenomenon: soil provides us with food, biomass and raw materials; human activities take place on it and it’s part of the landscape and our cultural heritage.

Which structures are more subject to surface erosion?

The areas of application most affected by the erosive action of the climate are:

- slopes and the sides of landfills and contaminated sites, and those that have been grassed for appreciable aesthetic improvement;

- reinforced earth structures, more specifically terracing in vineyards and the embankments of canals or rivers;

- ascending/descending ramps from flyovers, tunnel entrances and noise barriers on roads and railways;

- dry, rocky slopes, of all angles, that shape the terrain of Italy.

The effects of surface erosion

The uncontrolled removal of the surface topsoil and the failure of vegetation to take root results in ‘thinning’ of the soil and a risk to the stability of sloping areas.

What can be done to prevent surface erosion?

We should begin by pointing out that a case-by-case assessment is required that considers many variables, such as the nature and uniformity of the soil, the slope gradient, the type of slope (dry or rocky) and the weather conditions in the area where intervention work is to be carried out.

In general, vegetation, whatever type it is, has a natural ability to protect soils from erosion. So the best course of action is to quickly encourage grassing and then apply biodegradable mats made of jute, straw, coconut and cellulose fibre, which can also be pre-seeded.

TeMa Geo Solutions recommends biomats such as Ecovermat, Ecovermat P and PC, and Ecovernet.

Alternatively, or combined with these, synthetic geomats, mainly made of polymer monofilaments, can be used.

Once laid, they are covered with another layer of soil: in this way, the roots of growing vegetation will become entangled with the geomat, creating an almost permanent erosion protection system.

Once again, TeMa Geo Solutions offers a wide range of geomats to choose from.

Uncertain about what to choose? We can help you. CONTACT US!

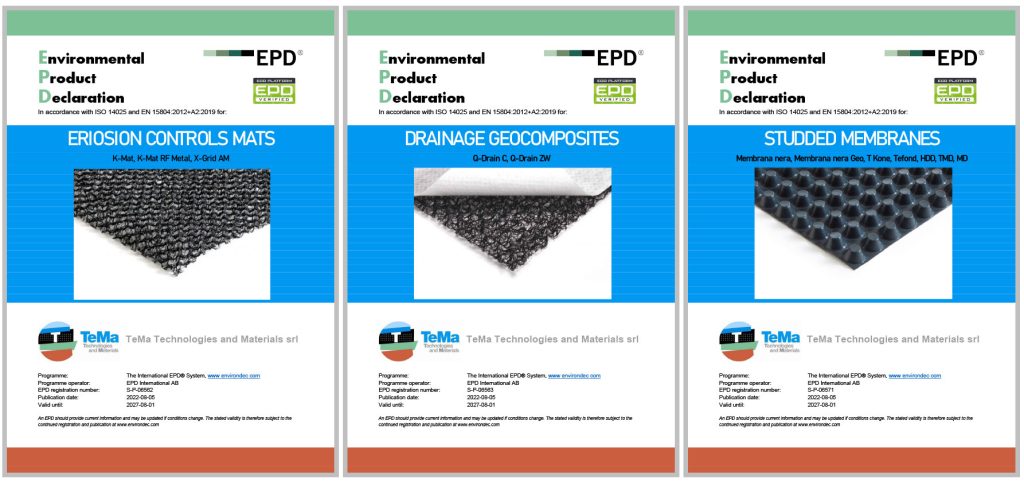

TeMa even more transparent about sustainability

With the new EPD certification, TeMa Technologies and Materials provides information about the level of sustainability of its products: this includes most of the membranes and geocomposites manufactured on its production lines. For 30 years, TeMa has regarded environmental protection as a duty and obligation towards the community and future generations.

What is EPD and what is analysed to obtain it?

The Environmental Product Declaration (EPD) is a document that provides specific data on the life cycle of products or a service. It measures the impacts that the production and life phases of a product have on the environment by means of a Life Cycle Assessment to determine the consumption of resources such as water, materials and energy.

It is voluntary and verified by the independent third party SGS so that certified declarations can be given to clients.

International acknowledgement

The EPD document is internationally acknowledged, as it complies with ISO standards. This ensures use, credibility and stability over time, making the data collected available for use in any type of environmental management system and providing information for environmental certification protocols for buildings and infrastructures.

Which product lines from TeMa Building Solutions are EPD certified?

The products having obtained EPD certification are:

- the studded membrane line, which includes Membrana Nera, Membrana Nera Geo, T-Kone, Tefond, HDD, TM and MD;

- the monofilament drainage line comprising Q-Drain C and Q-Drain ZW;

- the anti-erosion and reinforcement geomat line, which includes K-Mat and X-Grid AM.

Our certificates can always be consulted by clicking here and entering TeMa in the filters.

- Published in CORPORATION, news, TeMa Technologies and Materials

Concrete industrial paving: How to ensure versatility and durability

A factory layout determines the physical positioning of machines, workstations that develop individual processes and service departments in order to make the work of people, machines and materials more efficient.

Paving is subjected to continuous stress and have to withstand considerable loads. Concrete has its own characteristics to meet these needs and is also very aesthetically versatile, which means that it’s often used by designers in domestic and commercial contexts, both indoors and outdoors. Moreover, it can be quickly customised with textures or other types of printing.

What functions are important in industrial contexts?

Industrial paving inevitably suffers wear and tear from prolonged and intensive use.

It is therefore necessary to guarantee high compressive strength. This is because the surfaces of environments such as warehouses and industrial facilities are constantly subject to heavy loads: storage shelving systems, machinery and moving vehicles such as pallet stackers and forklift trucks. In many cases, weights are concentrated more in some places than in others (e.g. the areas where pallet stackers move or the quintals of goods in the warehouse that weigh down on the same spot for a long time).

This can also cause fissures and cracks on the surface that would hinder access and make it difficult to carry out normal work activities.

Lastly, as already mentioned, concrete is a very versatile material that can be laid over other types of substrate and also customised as required.

How to achieve an optimum and long-lasting result?

Thorough planning from the outset and the choice of suitable materials is the first step to a successful result, but painstaking attention during laying is also important.

The product range from TeMa Building Solutions includes specific products for the reinforcement of this type of paving. T-Fiberglas CLS mesh, made of fiberglass and coated with a special alkaline dressing, is designed to reinforce horizontal concrete applications, whereas T-Zink Net is the anti-cracking mesh made of galvanised steel.

- Published in BUILDING, Concrete paving