TeMa, laser focus on the future for 30 (+1) years

TeMa Technologies and Materials has just celebrated thirty years in business. A spin-off of Tegola Canadese, it was actually established in 1993 with the aim of expanding its presence into the commercial, civil and geotechnical construction space. Focused on products and systems to protect building foundations from rainwater and groundwater, the company went on to gain impressive international experience, becoming a go-to provider for the making safe of landfills, handling of contaminated sites, and soil reinforcement systems with solutions designed to be increasingly resilient, even in the face of extreme weather events.

TeMa is headquartered in Italy and is present on four continents with facilities in Italy, the US, South Africa, Spain, Turkey, India, Romania and Russia. Our sales are projected to reach the 100 million euros mark, demonstrating significant growth, doubling our 2021 revenues. A 100% increase within the space of just four years.

Rapidity, speed and reliability are the cornerstones of our relationship with the market, qualities that are paired with innovation, development of human resources and a strong environmental commitment. This sense of environmental responsibility is linked to the fact that our main manufacturing facility is located in an industrial area in Vittorio Veneto set between the unspoilt forests of the Cansiglio plateau and the hills recognized as a UNESCO World Heritage site. A heartfelt respect for the region that we’ve proudly professed from day one of our industrial journey.

This is why, for TeMa, sustainability is about much more than just green claims: we recover quality plastics through two recycling plants for the reuse of polypropylene and high-density polyethylene, one in Russia and one in Romania. All waste materials are sorted and put through grinding, washing and filtering cycles, before being extruded and used to make new products.

Over our 30 (+1) years in business, TeMa has risen to the sustainability challenge with a growing awareness of the importance of this issue, coming up with environmentally friendly solutions for geotechnical applications. One notable example is our range of products for the construction of “reinforced soil retaining walls”, in addition to our specialist area: the development of innovative and effective materials for use in embankments, road ditches, hillside terracing, landfills and contaminated sites. TeMa earth-retaining systems use the actual soil in place of traditional reinforced concrete products, encouraging vegetation growth and being undeniably better for the landscape. Our solutions include geonets, geomembranes and metal structures featuring different angles, designed to support the soil on their own and control rainwater. Many applications include the use of pre-seeded biodegradable matting.

With TeMa products, processes can now be employed that enable a considerable saving in terms of the CO2 emissions involved in handling materials. The resulting reduction in environmental impact is amazing! By doing away with the need for gravel and instead using the soil excavated on site, the energy used to transport materials is kept to a minimum. This approach means structures can be built to be impact resistant, withstanding even violent weather events, which there has certainly been no shortage of in recent years.

TeMa stands as a bastion of modernity in the industry, forever trying out competitive technologies — in our laboratories — in order to come up with simple and efficient materials, products and systems. These solutions are underpinned by research, experimentation and testing: a team of professionals — men and women, engineers and technicians — who all bring their individual area of expertise to the table and are driven by a commitment to customer outcomes, offering support, assistance and an attentive ear.

While ESG (Environmental, Social, Governance) factors are only now becoming mainstream among many businesses, these issues have always been at the very core of TeMa’s corporate philosophy. TeMa products have helped save thousands of loads of aggregate from being quarried and transported over the last thirty-plus years, which has had an extremely positive impact on the environment.

- Published in CORPORATION, Research and development, TeMa Technologies and Materials

Why TeMa?

TeMa Technologies and Materials is a brand operating in 80 countries worldwide with a business network and specialised distributors. An extensive sales network, regional agencies and a technical sales department are supported by an efficient customer service and functional logistics. But the most distinctive characteristic of TeMa, recognised internationally, is its strong drive for innovation.

A permanent feature is the innovative aspect of its products, solutions and processes, as well as its participatory research, reflected in organised meetings, technical seminars and international partnerships.

A solid technical sales organisation

We see the 30-year milestone that we have just celebrated with our collaborators as a start-up towards the future. With our training and experience in technical and sales areas, and the support of our distributor network, we can further enhance our ability to offer tailor-made solutions to all customers.

Indeed, our strong ties with the international market and highly skilled professionals encourages our technicians to make continuous improvements. Our business model sets us apart, making the products and services we offer unrivalled.

We also greatly value the development of ideas that takes place by exchanging experiences during training courses for our in-house employees and advanced courses in skills and competences for our external collaborators. This highly customer-centred business model aims to meet their needs while guiding decisions with solutions adapted to each situation.

TeMa constantly pursues certified quality

In our R&D department, we design and test new solutions and technologies to provide our customers with innovative products. Along with experimentation, this has enabled us to achieve several international patents.

We carry out daily tests regarding durability, compressive strength and drainage capacity in the most critical cases to ensure that our products deliver the expected properties. Each product placed on the market must comply with the stringent quality standards stipulated.

It is in this relentless verification of excellence that TeMa has implemented a UNI EN ISO 9001-certified quality system, documenting top performance across the whole production process. In compliance with the CPD (Construction Product Directive) 89/106/EEC, the product ranges TeMa offers have followed the procedure to be awarded the CE mark.

We monitor and optimise all aspects of the work and provide various services:

- Testing on raw materials.

- Inspection of finished products and prototypes for quality and performance.

- Compilation and updating of product Safety Data sheets.

- Quality control.

- Production process supervision and control.

- Sample testing of production lots and compliance checks.

Consultancy and technical support.

Our in-house technical department is on hand to assist customers, from choosing the solution through to its implementation, for any type of application.

Our technicians provide support for the sales network and assist customers in choosing the most appropriate products to solve each specific technical problem and meet specification requirements. This is achieved by analysing all relevant variables and providing complete and comprehensive technical specifications and installation methods.

Any upcoming projects? Contact us! We can help you choose the most effective solution.

- Published in CORPORATION, Research and development

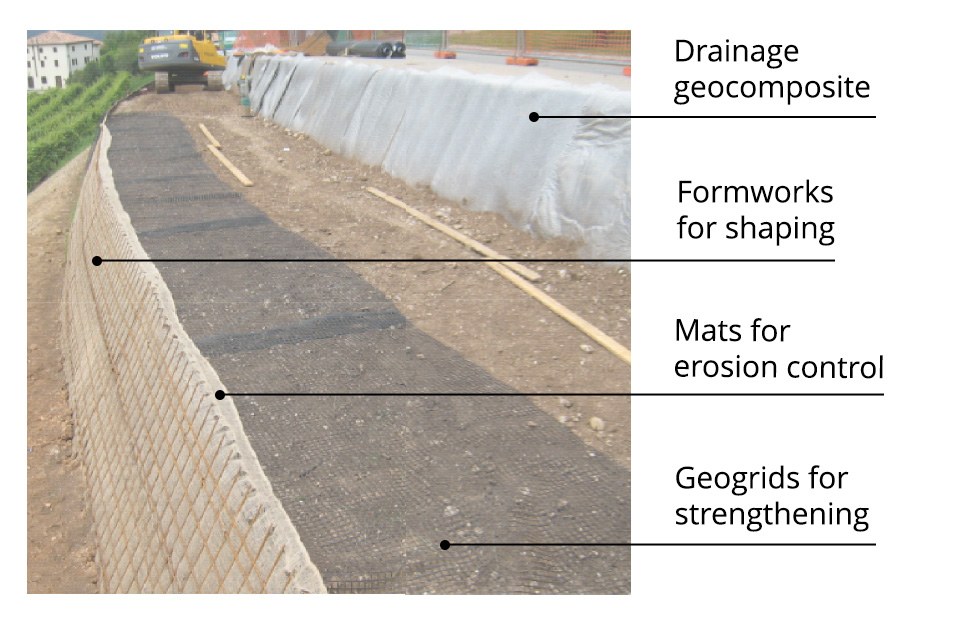

System for reinforced soil retaining structures

T-System is the system from TeMa Geo Solutions that includes various components for strengthening, surface erosion control, drainage and retaining used in the construction of reinforced soil retaining structures: innovation that we’ve been exploring here at TeMa since our inception 30 years ago, and that is now one of our hallmarks. Let’s take a more detailed look below.

Components for strengthening

Designed for strengthening, the knitted X-Grid PET C geogrids are made from high-strength polyester yarn, with a protective polymer coating. They deliver tensile strength in the 20 kN/m to 800 kN/m range.

Components for erosion control

They protect the face of the structure from erosive agents, like wind and driving rain, until the vegetation has had time to establish. TeMa Geo Solutions offers natural solutions made from cellulose fibres, like Ecovermat, or jute fibres, like Ecovernet, as well as synthetic solutions made from monofilaments (K-Mat F), polypropylene (K-Mat FA) or fibreglass (K-Mat FG Green).

Components for drainage

Drainage geocomposites like Q-Drain are used to address the problem of water seeping into the backfill.

Components for retaining

We have a line of facings made from electrically welded wire mesh — with inclinations ranging from 65° to 80° — to ensure the exposed face is straight.

Practical tips

On site

System components must be stored well away from machinery, and suitably protected from dust or residues from work on site.

To avoid excessive overlaps and waste, the X-Grid geogrids must be cut to size using a suitable metal stand with metal trestles supporting a circular rod to be inserted inside the roll.

Erosion control components — whether biodegradable or synthetic — must be stored in a dry place and not in direct contact with the natural ground, so as to avoid laying problems later on.

Metal formwork must be stored well away from areas where machinery is operating, and carried in only when it is time to install.

During assembly, it is best to apply U-shaped strips of rubber or metal so that the geogrids can be wrapped correctly over the formwork without getting caught on the top of the bars. (see photo)

Special instructions

We advise against backfilling with silty and clayey material; at the very least, only use this kind of material after mixing it with aggregate.

The full range of system components comes with instructions on the relevant procedures to be followed. Contact us, we’ll be happy to provide case studies and full information.

Join us at Ecomondo 2023

Climate change and extreme natural events are having an impact on the planet’s life balance. The current international focus on the ecological transition and the circular and green economy is making it more and more imperative to make innovative decisions on this front. This is why our TeMa team of engineers and technicians will be attending Ecomondo 2023 to share with professionals, industry, stakeholders, policy makers, opinion leaders and local authorities just how significant a role our products can play in this green drive.

Ecomondo will be held from 7 to 10 November 2023 at Rimini’s exhibition centre. This is the leading international event on the European calendar for sharing and comparing strategies that will shape the EU’s environmental policy. Which is why it’s important to take part.

There’s a well thought out programme packed with conferences, seminars and workshops. Over the four-day show, the programme will tackle interconnected macro issues:

- Bioenergy.

- Circular and regenerative economy.

- Site and land maintenance.

- Waste as a resource.

- The water cycle.

- Environmental control and monitoring.

TeMa champions renewable energy, recycling and sustainable geotechnical projects.

Over our 30 years in the business, and with ever-growing awareness, TeMa has ventured into the realm of sustainability, presenting environmentally friendly solutions for geotechnical projects.

Since our inception, we’ve specialized in reinforced soil solutions for road embankments or ditches, slopes and hillside terracing, landfills and contaminated sites.

No matter what the situation, even in an urban context, there are always green solutions to take the place of concrete. Our catalogue features products that are as high performance as they are sustainable, like biodegradable matting (including pre-seeded mats), geonets and geomembranes. When it comes to handling, there are considerable CO2 savings: there’s no need for gravel, and the soil required is found on site, so no added carbon footprint.

What’s more, our geogrids have earned their reputation as a key substrate in road construction, built to provide lasting strength and withstand cracks or minor subsidence, resulting in a smoother ride and safer road surface.

Join us! We look forward to showing you some of our past projects from around the globe, and some cost-effective and intriguing solutions, such as a horse racing track produced in South Africa built to cope with pounding hooves, even after rain.

We’ll be attending Ecomondo to showcase our solutions, as well as our business decisions:

Part of our products are made using pre-used plastics we “recycle” in our own plants.

We’ve set up two collection and recycling plants (in Russia and Romania) to handle high-density polyethylene, and polypropylene: we sort the waste material, carry out two grinding and washing cycles, and finish with extrusion and filtration.

…we reuse washing water.

wastewater from the washing process is treated and reused for subsequent processes.

…we invest in renewable energy.

Almost 50% of the energy used in our production processes comes from renewable sources: three photovoltaic systems — with rated outputs of 200 kWp, 150 kWp and 100 kWp — and a cogenerator producing another 800 kWp.

Go here for more details.

Join us at the show!

You can find us from 7 to 10 November 2023 on Stand 506, Hall D1, at Rimini’s exhibition centre.

In the meantime, you can find out more about Ecomondo by checking out the official site: click here.

- Published in CORPORATION, Exhibitions and events, news, TeMa Technologies and Materials

Sustainable finance: sustainable development

It’s interesting to realize just how much the environmental culture of a business can be a way to accelerate its development, even by allowing it to access finance that’s vital for its growth and innovation: this is where the concept of sustainable finance comes in.

No self-respecting company report is complete without covering sustainability, the circular economy, wellbeing and the environment, which have different connotations for different businesses and are promoted to varying extents over the course of their lives.

The fact that this has become a “mature” issue can be seen in the need and, indeed, the will of companies to meet the requirements of ESG “certification” (Environmental, Social and Governance), since those companies who are attuned to these worlds are destined to have a more productive future and be more attractive to financial backers.

So, by sustainable finance we mean finance that supports the capital and investments of businesses with future-proof projects, especially from an environmental point of view. This is a practice aimed at investing to develop production processes, in addition to funding research into raw materials and end-of-life disposal of products, with the upstream decision process generally focusing on protecting the planet.

The cornerstones of sustainable finance

There are three factors taken into consideration, into which the tangible application of sustainable development can be narrowed down.

- Environmental factors: these include issues like the need to promote greener, more energy-efficient production processes. They very much hinge on the themes of circular economy and zero-emission activities, as well as on preventing pollution and protecting biodiversity.

- Social factors: these focus more on reducing inequality and on developing an inclusive system, one that is pro-human rights, in addition to investing in training and in the wellbeing of communities.

- Governance factors: these ensure that both environmental and social factors are included in the company‘s decision-making processes.

TeMa and sustainability

TeMa Technologies and Materials has long been a believer in using sustainable materials and creating sustainable solutions, even in the building and geotechnical fields.

Reinforced soil projects, on both a small and large scale, are a case in point: the technique of using soil as a retaining material, instead of concrete, certainly makes the structure more environmentally friendly, providing benefits in terms of both the landscape and liveability (they often double as noise barriers, click here for more information).

We provide 30-plus years of experience in the development of geogrids and geomembranes supplied in rolls, which are easy to carry to even the most inaccessible sites, and are ideally suited to the construction of landfills, tunnels, roads, reinforced soil projects and drainage ditches.

In addition to the many advantages in terms of construction, they come with the no small benefit of energy savings and the reduction in air pollution achieved when using geomembranes instead of traditional gravel: in terms of transport alone, the number of trips (trucks) drops from 100 to 1.

Out of our many past projects, one standout would have to be the track of a race course in Johannesburg, in South Africa.

In addition, TeMa supplies sustainable products like natural fibre matting — made from materials such as jute, straw, coconut and cellulose — that are particularly well suited to surface erosion control on grass slopes.

- Published in CORPORATION, Research and development, TeMa Technologies and Materials

Lifelong learning

The term lifelong learning refers to the process aimed at ensuring skill levels keep pace with new professional needs and market innovations as they emerge. In the field of residential, commercial and infrastructure construction, technologies and work processes are developing constantly and at a heady pace, driven by research and by the demands of designers.

Over our 30 years in the business, TeMa Technologies and Materials has interfaced with numerous entities, has broadened its product range and, above all, has researched and come up with solutions that cater to the technical, business and logistical requirements of a fast-evolving market. TeMa’s allure lies in our close relationship with designers and operators, being there to provide support and spearheading training and ongoing learning.

So, while competition is strong, here at TeMa we respond to the challenge with professional growth, specialization and refresher training. The new developments and the skills that put us in a position to tackle challenges, site after site, project after project, are all part of our end customer focused approach.

We’re all convinced that sound technical learning can make all the difference when it comes to the success of even the most ambitious projects, which is why we expect our in-house personnel to engage with this learning, and why we also offer training to all the people choosing our solutions each day.

We offer monthly webinars and in-person meetings during which we explore the issues to be dealt with in each specific field, along with legislative aspects and technical aspects, above all leveraging practical examples, because hands-on experience promotes learning.

The meetings, which are almost invariably accredited, last anything from a few hours to a whole day, allowing attendees to explore the subjects in depth, ask questions and seek clarification from our experts.

- Published in CORPORATION, Research and development, TeMa Technologies and Materials

Literally putting them to the test.

Ensuring that products fulfil the required functions and standards has been our mission since the outset of our company. All materials exposed to sunlight, moisture and temperature changes are exposed to the damaging effects of nature. There’s also erosion due to rain, which can play a major role in the deterioration of many building materials.

It’s therefore important to work with institutes that have weathering test equipment and expertise in testing services for the building materials industry, for residential and commercial construction.

Why it’s important to test solutions

Each company like ours aims to meet the expectations of those who choose it and, of course, to comply with all applicable regulations. Testing the solutions we provide allows us to guarantee performance also under critical conditions, offering our customers cutting-edge products, and to support designers in planning and installers during the installation stage. As for innovation, our customers’ expectations are always very high: indeed, dozens of new products are being tested and waiting to be introduced into the market.

The tag-line of the specialised divisions of TeMa is ‘Solution’ and, to be true to this requirement, a product must meet a series of specifications of on-site competitiveness, service effectiveness and a long life.

The tests involve special equipment for testing durability, compressive and tensile strength, drainage capacity and mechanical protection, ventilation and vapour diffusion performance, thermal and corrosion resistance… as well as many other functions viewable here.

This is all achieved as a result of the close connections between our Technical Department, where market demands are examined and possible solutions studied, and Labs, where tests are carried out to check performance and guarantee performance parameters. By working with accredited independent external labs for testing procedures, we can improve throughout all stages of the production process.

Our certifications

CE marking is featured on all product lines in our catalogue, in compliance with the CPD (Construction Product Directive) 89/106/CEE. The pursuit of excellence has led us to implement a certified quality system, UNI EN 3001:2000, which ensures performance levels throughout production. We also hold various international patents.

Activities at TeMa labs

- Raw material testing: we check the quality of raw materials.

- Support for R&D: our solutions are the result of continuous research into market requirements and constant improvements.

- Supervision and monitoring of production processes: we check that production processes comply with standards and the studies undertaken.

- Quality and performance testing of end products and prototypes: tests to check performance, initially of prototypes followed by end products.

- Spot tests on production batches and conformity checks: on end products and by testing application solutions.

- Quality control: we check that products meet the standards of individual countries and the required performance.

- Drafting and updating of product data sheets: each product has its own data sheet, promptly updated, with technical data indicating its performance.

- Certifications: those required for each country in which we operate and the environmental certifications to be guaranteed for our customers.

Find out more on the dedicated page of our website.

- Published in CORPORATION, Research and development, TeMa Technologies and Materials

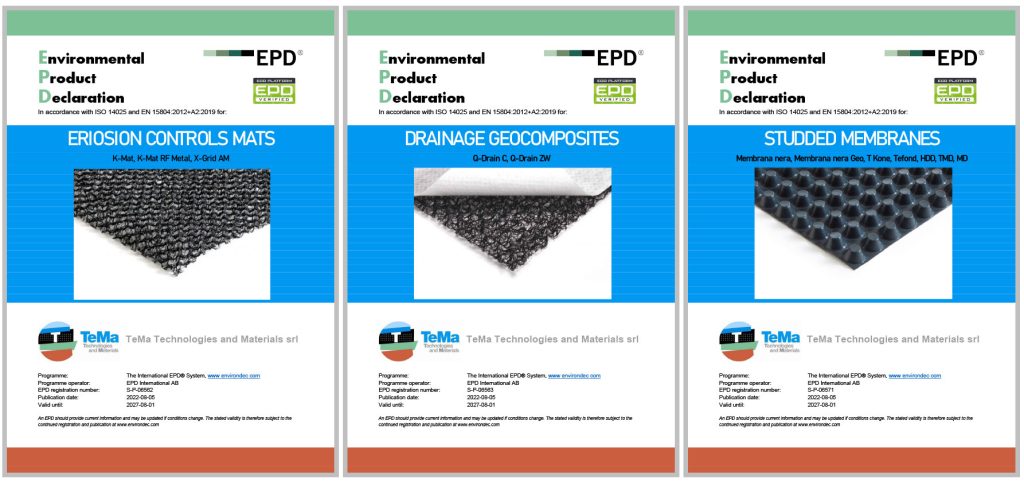

TeMa even more transparent about sustainability

With the new EPD certification, TeMa Technologies and Materials provides information about the level of sustainability of its products: this includes most of the membranes and geocomposites manufactured on its production lines. For 30 years, TeMa has regarded environmental protection as a duty and obligation towards the community and future generations.

What is EPD and what is analysed to obtain it?

The Environmental Product Declaration (EPD) is a document that provides specific data on the life cycle of products or a service. It measures the impacts that the production and life phases of a product have on the environment by means of a Life Cycle Assessment to determine the consumption of resources such as water, materials and energy.

It is voluntary and verified by the independent third party SGS so that certified declarations can be given to clients.

International acknowledgement

The EPD document is internationally acknowledged, as it complies with ISO standards. This ensures use, credibility and stability over time, making the data collected available for use in any type of environmental management system and providing information for environmental certification protocols for buildings and infrastructures.

Which product lines from TeMa Building Solutions are EPD certified?

The products having obtained EPD certification are:

- the studded membrane line, which includes Membrana Nera, Membrana Nera Geo, T-Kone, Tefond, HDD, TM and MD;

- the monofilament drainage line comprising Q-Drain C and Q-Drain ZW;

- the anti-erosion and reinforcement geomat line, which includes K-Mat and X-Grid AM.

Our certificates can always be consulted by clicking here and entering TeMa in the filters.

- Published in CORPORATION, news, TeMa Technologies and Materials

We will be at the EuroGeo7 Conference in Warsaw

After being postponed for so many months due to the health emergency, EUROGEO7, the 7th European Geosynthetics Conference will take place at last in Warsaw from 4 to 7 September 2022. We will be participating with our thirty years of experience and our innovative flow of products and functions.

We will be attending with ourTeMa Geo Solutions division, specialized in developing innovative technologies and products for protection, maintenance, retention, reinforcement and drainage in environmental works.

We have achieved these goals because since 1993, when TeMa was established, geosynthetic products have been our targeted approach to geotechnical and environmental applications. At a time when there was little talk of ecosystems, we developed considerable experience in this field, deploying new technologies and finding crucial improvements in terms of durability and less invasive intervention works using geosynthetic products.

The many fields of application range from the most important functions to be addressed in the fields of geotechnical engineering, reinforced earth structures and reinforced soil, to name but a few. They are highly impressive in the fields of hillside agriculture and the urban regeneration of small villages: drainage and filtration for landfills and contaminated sites; roads, railways and other transport applications; rainwater management.

What will TeMa Geo Solutions explore?

The focus is on geosynthetic products and the aspects that make them versatile, high-performance and innovative in geotechnical engineering applications. In particular, we will be focusing on TeMa Geo Solutions technologies for:

- removing seepage water using drainage geocomposites bonded with a nonwoven geotextile;

- reinforcement and stabilization with geogrids;

- the drainage capacity for the cap, bottom and sides of landfills with geonets;

- erosion control and drainage with geomats.

Our technicians will be available to provide catalogues and data sheets with performance details.

To learn more: https://www.temacorporation.com/geo-applications/

- Published in CORPORATION, Exhibitions and events, news, TeMa Technologies and Materials

Proud to be BEE certified

Our strength is that we never stop striving for the best, in everything: we are at the forefront in researching new materials, studying innovative solutions, focusing on the environment and exploiting resources… We couldn’t be any less inclusive.

Our company operates worldwide, we have branches in practically all continents and the concept of ‘internationalisation’ is our daily bread. We have always worked in contact with different people and cultures and have no difficulty in approaching them: it comes naturally to us!

We are therefore delighted to have been awarded BEE certification for our TeMa South Africa division.

What is it and how does it work?

Broad-Based Black Economic Empowerment, or B-BBEE, is a South African government initiative that encourages businesses to integrate more black citizens into all jobs, from employees to entrepreneurs, and reduce inequality in income.

The assessment is made based on 5 parameters:

- Ownership: voting rights and shareholding in the company

- Management control: members in management roles and voting rights with control over the board of directors

- Skills development: learning opportunities for developing new skills

- Enterprise development: support and development of small businesses run by black people

- Socio-economic development: corporate investment in economic and social initiatives.

Each parameter is assigned a value that creates the final percentage score, which is used to assign the category level. There are 8 of them, proceeding in descending order: 1 is the level with the highest score, 8 with the lowest score.

TeMa South Africa has been assessed by the EmpowerBEE certification agency and is a certified collaborator at Level 3 – 110% procurement recognition level.

We aim to improve further in order to reach the highest level.

Click here to find out more.

- Published in CORPORATION, news